Highlight

New Magnetic "Smart Material" Developed through Collaborative Alloy Processing and Modeling at Texas A&M

Achievement/Results

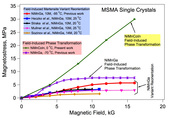

In the last year Texas A&M faculty members Ibrahim Karaman (Mechanical Engineering) and Dimitris Lagoudas (Aerospace Engineering) have developed a new alloy based on Ni, Mn, Co, and In, which can exhibit a very large actuation force induced by a magnetic field. Karaman and Lagoudas are members of the NSF-funded Integrative Graduate Education and Research Traineeship (IGERT) program “New Mathematical Tools for Next Generation Materials,” and also have NSF funding from the Division of Materials Research for this work. Traditional Shape Memory Alloys have a number of important applications in medicine and aerospace. In the traditional alloys, the physical transformation is driven by temperature change, however the latter process is slow, which significantly limits the further practical use of these materials. Recent studies of Magnetic Shape Memory Alloys (MSMAs), in which a magnetic field drives the physical transformation, rather than temperature change, promise many new applications. The figure shows how the new NiMnCoIn material (upper curve) exhibits a significantly larger actuation force than other known MSMAs, as a magenetic field is applied (horizontal axis). This advance was based on materials design and development in Karaman’s group, where large single crystals of this material were achieved, and through microstructural modeling efforts led by Lagoudas. Through the latter studies this team recognized that a new mechanism underlies the actuation behavior of this material, distinct from that of other MSMA’s. Other IGERT faculty members involved in this effort include Tahir Cagin (Chemical Engineering), who is modeling the transformation energies from an atomic perspective. Additional interdisciplinary research efforts have developed out of the MSMA work this year, including the funding of a new NSF Nanoscale Interdisciplinary Research Team (NIRT) including Karaman, Lagoudas, with IGERT advisor Xinghang Zhang, and the development of a larger MRSEC center proposal, including six additional IGERT faculty from Texas A&M and Prairie View A&M Universities, built around the themes of the NIRT and IGERT initiatives. The Texas A&M Colleges of Engineering and Science also agreed to fund a new magnetics laboratory based on the successes of the magnetism-related research in this group.

Address Goals

This research can have a number of important benefits for the US. For example, smart materials that respond to varying conditions could be used to improve the efficiency of automobiles and aerospace vehicles, thus providing significant energy savings. This advance is directly related to the theme of the New Mathematical Tools for Next Generation Materials IGERT, and the work has catalyzed new collaborative work among IGERT faculty as described above. Students from several departments and differing backgrounds will participate in the further development of these issues, for example first-year trainee Kristen Williams will proceed to her next research experience developing ab-initio models of the alloy behavior of these materials in June 2008, and incoming trainee Cengiz Yegin will be involved in experimental alloy development efforts over the summer of 2008. Thus this work will help to cultivate a workforce ready to address interdisciplinary materials development problems to meet future needs. In addition this work has led to the enhancement of the infrastructure for materials research at Texas A&M, laying the needed foundation for future developments based on this work, for example the development of microfabricated devices based on these new materials. The latter is the theme of the newly funded NIRT project, bringing together a core of IGERT research groups.