Highlight

Neutron Imaging of Oscillating Heat Pipes

Achievement/Results

Profs. Bill Ma and Robert Winholtz and their team at the University of Missouri have successfully applied neutron imaging techniques to observe the inner workings of oscillating heat pipes (OHPs). Their achievement is significant because OHPs are components that show great promise for removing excess heat generated in a variety of commonly used electronic devices including computers and optical instruments such as lasers. In fact, OHPs are able to conduct heat up to 80 times better than pure copper. An OHP consists of a working fluid such as water or acetone in an evacuated metal tube that winds back and forth between a source of heat (e.g., a computer) and a heat sink (e.g., aluminum cooling fins) as shown in Fig. 1.

The high thermal conductivity of OHPs results from flow of the working fluid between the hot and cold sides of the OHP driven by pressure differences developed from evaporation and condensation of the fluid at the heat source and heat sink, respectively. However, the detailed mechanism of operation is not well understood because one cannot see inside the opaque metal tube with visible light or x rays. On the other hand, neutrons can easily penetrate the walls of the copper and aluminum tubes used in OHPs but are greatly attenuated by the hydrogen-bearing fluids within. Neutrons thus provide a unique way to image the fluid phases inside an OHP analogous to the use of x rays for medical imaging.

Address Goals

The right panel of Fig. 1 shows a neutron image of an OHP, while it is operating. At the NIST Center for Neutron Research in Gaithersburg, MD, Ma and Winholtz’s team can obtain neutron images at a rate of 30 times a second to record a video of the fluid motions inside the OHP. In this way, they have gained a much-improved understanding of the fluid movement and heat transfer mechanisms. These experimental observations are being used to improve mathematical models of the OHPs that will allow design of OHPs with better thermal conductance.

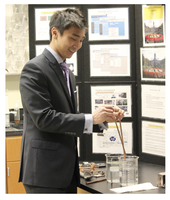

In Fig. 2, IGERT trainee, Feng (Tom) Zhang, demonstrates a conventional heat pipe at an Engineering Open House at the University of Missouri. Zhang won the prize for best lab presentation at the Open House.

References:

1. I. Yoon, H. B. Ma, and R. A. Winholtz, “Effects of Liquid Fraction and Vapor Volume on the Oscillating Temperature in an Oscillating Heat Pipe Using Neutron Imaging,” Heat Transfer Research 44, 43-57 (2013).

2. C. D. Smoot, H. B. Ma, R. A. Winholtz, D. L. Jacobson, D. S. Hussey, “Thermal and Visual Observation of a Hybrid Heat Pipe,” Heat Transfer Research 44, 31-42 (2013).